Dibal GW 4500 high speed automatic weight check and sorting machine, sorts the product according to weight ranges, up to 162 packages per minute without stopping. The machine can be configured with up to 6 weight ranges and ejection systems. Several types of ejection system are available depending on the product and / or operational setup. Products are weighed and sorted according to the preset weight ranges then diverted by the applicable ejection system, into a collection bin or onto a separate conveyor.

Weighing range:

- Max. 3 kg / 1 g on conveyor:

- Max. 6 kg / 2 g on conveyors:

400mm (L) x 280mm (W)

400mm (L) x 400mm (W)

600mm (L) x 280mm (W)

- Max. 15 kg / 5 g on conveyors:

600mm (L) x 400mm (W)

800mm (L) x 280mm (W)

800mm (L) x 400mm (W)

Ejection system:

Types: *

- Air-jet / air blowing

- Pneumatic piston

- Swiveling bar

- Push bar

Number of ejectors:

Position of the 2 ejectors:

- They can be located on the same side or opposite sides.

Construction:

AISI 304L stainless steel and anodised aluminium

- Standard

- Non-slip

(for high-speed applications)

- Sliders

(for ejection conveyors)

Display console:

- Dot matrix display console with keypad

- 15-inch TFT touch screen

(if applicable)

Connectivity:

- TCP/IP Ethernet

- Serial RS232

Power:

230v AC single-phase

Compressed air:

Max. 150 litres / minute (at 6 to 8 bar for the ejection system)

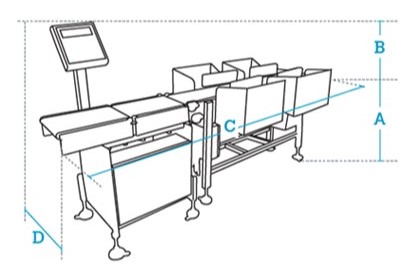

|

|

| A |

850mm to 950mm (adjustable height) |

| B |

600mm |

| C |

2,356mm ** |

| D |

630mm *** |

* All ejection systems depend on the type of product/packaging, required speed, collection system, etc.; please contact us.

** These measurements correspond to the sum of the 400mm (L) infeed, 400mm (L) weighing and 4 optional rotating blades ejection system conveyors. For other sizes, please contact us.

*** For 280mm wide conveyors without buckets. For other sizes, please contact us.

Non-motorised PVC exit rollers for 200mm, 280mm and 400mm wide conveyors

Visual and audible alarm (24V)

Polycarbonate protector for the weighing conveyor